The vast portfolio of products and solutions in the SPX® FLOW portfolio are supported by leading application and process expertise. They are designed to offer high value performance in applications across chemical, oil & gas, water & wastewater, power generation, pharmaceutical, food & beverage and many other industries. Its impressive combination of experience and technology, makes SPX FLOW an ideal partner to help you optimize process and operational efficiency and get the best return from your investments. At this year’s ACHEMA exhibition, SPX FLOW will be highlighting many of its leading brands and products including pumps, filtration, heat exchangers, hydraulic tools, chemical analysers and mixing solutions.

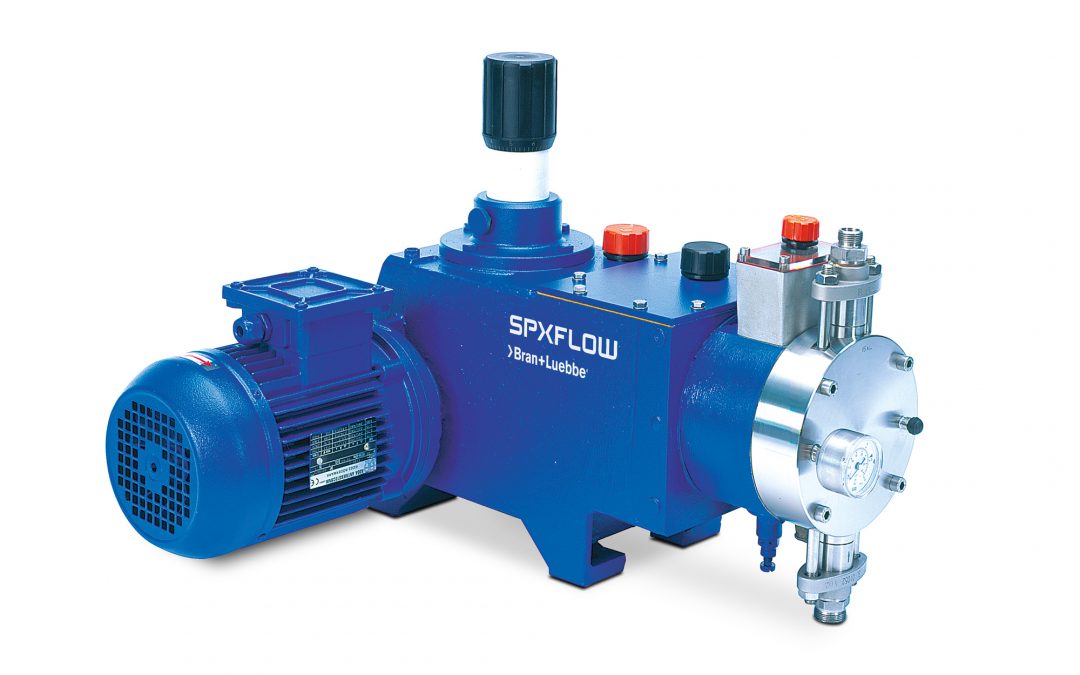

SPX FLOW has one of the widest range of pumping solutions. At ACHEMA it will be displaying its Novaplex Vector process pump and H-Range metering pumps, from its Bran+Luebbe brand. The Novaplex Vector is a cleverly designed triplex diaphragm pump with pump heads arranged in three dimensions to create a smaller footprint. It has a robust diaphragm pump head design, that can operate in potentially hazardous areas, provides remarkable pumping reliability and is designed for straightforward maintenance.

The stand will also contain TRIRO triple screw, positive displacement pumps from SPX FLOW’s Plenty brand. These proven pumps for medium to high pressure applications provide reliable, pulse-free operation for pumping oils. From the ClydeUnion Pumps (CUP) brand, SPX FLOW will be highlighting the benefits of its CUP-BB5 range of multi-stage, radially split barrel pumps. These pumps, designed against the latest API 610 oil industry specification, provide comprehensive hydraulic coverage with performance that is well-proven in the field. The CUP Uniglide-e pumps will also be shown. These axially split, double entry pumps have low NPSH and offer high efficiency, low maintenance and exceptional reliability to reduce the total cost of ownership.

Continuing with the vast range of pumping solutions, SPX FLOW will further be showing its new TopLobe Plus (TLP) Pump and CombiSump Top Wing pumps from its Johnson Pump brand. The versatile TLP Series pumps offer customers exceptional value and hygienic performance with low shear and gentle product handling for both high and low viscosity products.

When it comes to mixing solutions, the SPX FLOW Lightnin brand offers customers a unique range of technology, experience and support in finding the best solution for their applications. Along with a range of other mixing technology, at ACHEMA it will be demonstrating its LightninMiniLab™; a compact mixing laboratory that can be shipped to plants throughout the world for onsite testing to establish optimum mixing processes.

Other technology on display will include the innovative Bran+Luebbe PowerMon analyzers. These analyzers give highly accurate, stable results for even the lowest chemical concentrations. They help optimize plant performance, are economical to operate and assure the highest level of safety and reliability. With over 15,000 analyses possible, cost efficiency can be further optimized as a single unit can replace several single parameter analyzers.

Additional solutions on display will focus on the Airpel and Plenty Filters ranges of single and dual basket strainers, automatic self-cleaning and backflush filters and strainers. Experts will further be on hand to discuss the latest technology from the APV®, Pneumatic Products, Power Team and Bolting Systems brands.

SPX FLOW offers its customers a commitment to ensuring they are supported through all phases of their project or equipment lifecycle. Its understanding of processes and applications, well-equipped test facilities, continued investment in research and development and global support network, make it a partner which has proven time and again that its solutions can truly optimize processes and operations; delivering a reduced total cost of ownership and excellent return on investment.

Experts will be on hand throughout ACHEMA 2018 at Hall 4 stand #A49 and Hall 8 stand #L61.

For more information on SPX FLOW, please visit www.spxflow.com