Refrigerant gas leak detection is becoming a high priority for many companies, especially considering the increasing price of refrigerant gas, not to mention emergency service call-out costs to find, detect and repair leaks of hydrofluorocarbons (HFC), chlorofluoro-carbons (CFC), hydrochlorofluorocarbons (HCFC), Ammonia or CO2, and the potential for loss of inventory if a major leak renders a system inoperable. Installation of InfraRed Leak Detection Systems (IRLDS) is becoming increasingly important to be able to monitor for leaks in critical areas continuously. Along with the above concerns, depletion of the ozone layer is everyone’s responsibility to prevent further serious damage to the environment.

One of the most difficult areas of sealed system servicing can be trying to find a refrigerant leak. The refrigerant leak may exist within a series of tubing that may be up to hundreds of feet long or in a component that is not readily accessible or may even be, totally concealed.

Other sources of fugitive emissions of refrigerant gas are from refrigerant manufacturing plants, refrigerant storage or transfer stations. Area monitoring of these facilities can alert the proper authorities to initiate corrective action. IRLDS detection locates the sensing component at a central location, which can more easily be accessed for maintenance and calibration.

Based on PAS-technology (Photoacoustic Spectroscopy), the Innova 1412i is a highly accurate remote controllable field gas monitor, especially designed as core component for building and efficient area monitoring system.

Novel NDIR gas sensing solution for cost-effective detection of virtually all popular F-Gases

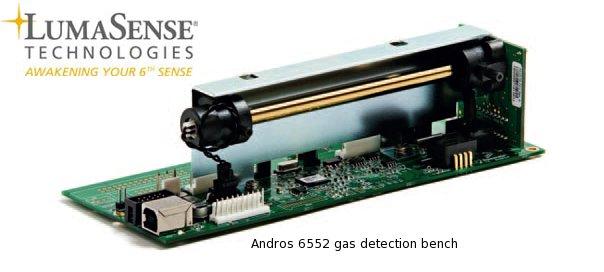

As very cost efficient gas sensing solution LumaSense offers the Andros 6552 detection bench, an NDIR –based gas measuring system for the OEM sector, which can detect concentrations of all common refrigerants in the ambient air.

The novelty about the Andros 6552 detection process is that this measuring technology can be adapted easily and inexpensively to virtually all F-gases, without the need for changing the hardware itself. This presents a unique benefit to the users, because now there is a large amount of different refrigerants, which all behave different.

These so-called F-gases or Freons are proven to seriously damage the general climate conditions as well as for causing destruction to the ozone layer. Therefore, according to the current “F-Gas Regulation”, passed by the European Parliament and the Council of the EU (EU no. 517/2014), all operators of larger cooling systems must ensure and positively take care that possible leaks are detected automatically and early.

The Andros 6552 gas detection bench thus constitutes the core of a corresponding leak detection measurement system. The employed technology is based on “non-dispersive infrared spectroscopy” (NDIR). It is a robust, high-precision and well accepted methodology to determine concentrations of specific gases in gas mixtures (such as air). Here, the absorption at a typical wavelength for the respective gas is measured in the infrared range.

The system is based on the proven technology of the Andros 6500 multi-gas sensors and is able to measure up to 5 gases simultaneously – three in the infrared range and two with electrochemical sensors.

Andros OEM NDIR gas analyzer products stand out for their extremely high reliability, low power consumption, and integrated pneumatic controller and power supply. In addition they are service friendly and do not need re-calibration, which results in very low cost of ownership.