The new system was developed exclusively with its partner company NANO 4 U and integrated into the Romaco Noack blister line 960.

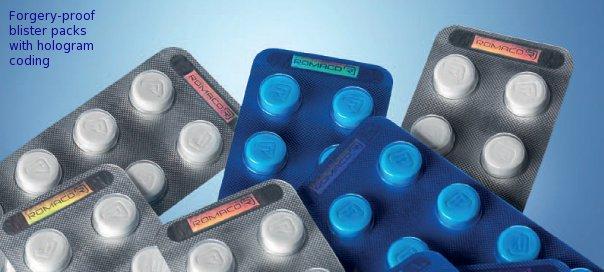

Anti-counterfeiting technology is an extremely important issue for global pharmaceutical producers and packaging contractors. In an exclusive partnership with NANO 4 U, Romaco has developed an anti-counterfeit solution for blister packaging that is suitable for pharmaceutical products and meets the EU Falsified Medicine Directive 2011/62/EU. At the ACHEMA, Romaco introduced the Romaco Noack 960 blister line with the new technology for unique primary packaging identification.

An anti-counterfeit packaging solution for pharmaceuticals

The new solution from Romaco for anti-counterfeit blister packs is based on a banknote authentication system. Romaco and its partner NANO 4 U took this technology further. The new system to protect the primary packaging of pharmaceutical solids can be integrated into all blister machines equipped with coding stations. An individual hologram stamp gives a unique indication of originality – in-line and without the use of additional materials. The individual blister packs are coded with overt and/or covert security features. Visible holograms with company logos, combinations of letters and digits, instantly identify the blister packs as originals. Invisible codes that can be verified quickly and easily can also be incorporated into the hologram. All you need for verification of a hidden logo or data matrix code, is a simple laser pointer.

Serious deterrent to counterfeiters

The use of anti-counterfeit and high precision stamps makes this technology a serious deterrent to counterfeiters. Whereas integrating the hologram stamp into the coding station of a Romaco Noack blister machine is very simple. The security features are applied using a heated coding tool without affecting production speed.

The Romaco Group

Romaco is a leading global supplier of Processing and Packaging equipment, predominantly for the pharmaceutical industry. Divided into three business areas, Processing, Tableting and Packaging, the company develops engineered system solutions for the pharmaceutical market, but also supplies the cosmetics, food and chemical markets. Romaco operates from four European locations with the headquarters in Karlsruhe, Germany.

The company serves the multiple industries through a total of eight brands: The packaging product lines Noack, Siebler, Bosspak, Macofar, Promatic and Unipac are manufactured in Karlsruhe, Germany and in Bologna, Italy. The tableting product line Kilian is produced in German Cologne while the Innojet product line in German Steinen is responsible for granulation and coating. Romaco’s product portfolio includes primary, secondary and final packaging, aseptic and non-aseptic liquid and powder filling, tablet press technologies, granulation and coating.

Over 12,000 Romaco installations are currently in operation in more than 180 countries. The company’s worldwide customer base is supplied and supported by over 500 highly skilled and committed employees.

In 2014 the Romaco Group was voted by “Wirtschaftswoche”, the prestigious German business weekly as one of Germany’s best 50 innovators among small and medium-sized enterprises. In this corporate benchmarking contest, Romaco was named runner-up in the “Process and Packaging Machinery” category. In the “Pharmaceutical Machinery” segment, the Group was awarded first prize.