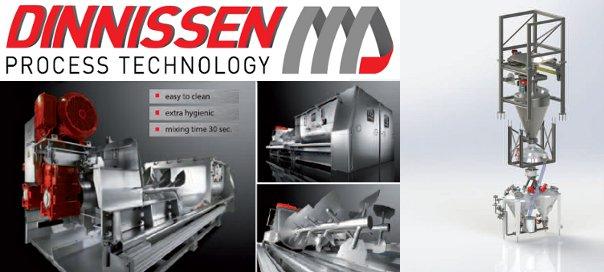

Dinnissen Process Technology develops and produces customized solutions for companies all over the world that enable them to handle and process powders, particles, and granulates quickly and efficiently. Its new and intelligent Plug & Play system is a crucial building block that allows its clients to easily install and operate complete production processes in a modular fashion wherever needed. Dinnissen is introducing its Plug & Play system at the Anuga Foodtech in Cologne and at the EasyFairs Solids in Antwerp.

3-D design programme makes design and development extremely efficient

In order to be able to export machines, solutions, and complete production processes to companies all over the world, it’s crucial to ensure that design, installation, and service are professionally organized. Dinnissen’s Plug & Play concept starts with the 3-D design phase of process solutions for its clients. This offers the client optimum visual insight into his customized solution early on in the design phase and also greatly increases the efficiency of the design phase itself. As Dinnissen’s Dinnissen presents Plug & Play concept for all its process technologies 3-D design programme is also linked to various processing machines at its production facility, the production of process equipment and solutions can be automated to a high degree and carried out much more quickly and efficiently.

Machines and production lines built in accordance with skid principles

Machines and even complete production lines are then built and installed in-house on a stainless steel or steel frame in line with skid construction principles. The control cabinet with PLC controls and HMI or PC Scada system are built and tested by Dinnissen in Sevenum to exact customer specifications. The systems are pre-wired for delivery in such a fashion that plugless cables can easily be fed through cable ducts at the client location. After the process components, including mixers, Big-Bag unloaders, bag emptiers, transport systems, and even complete production lines have been rigorously tested and approved, they are released to leave the production facility.

Management system for remote support a standard component

The Plug & Play process technologies produced by Dinnissen are then packed and transported in seaworthy containers. Upon arrival, the customer can easily install everything himself or have it installed. The supervisor from Dinnissen accompanying the shipment provides installation and operating instructions and monitors the entire process. A standard component of Dinnissen’s Plug & Play system is a management system that makes it easy for the customer to visualize the entire process. Dinnissen is a experienced Siemens and Alan Bradley provider and can therefore deal quickly and flexibly with any automation request submitted by the client. Dinnissen uses this management system itself to quickly provide remote professional support. Dinnissen’s Plug & Play concept has the advantage that all process components can easily be assembled in a modular fashion.

More information

Plug & Play greatly accelerates the installation process on-site and minimizes any resulting downtime. Customized Plug & Play process technologies are another example of the standard of quality provided by Dinnissen to leading companies such as Danone, Nestlé, FrieslandCampina and Cargill.