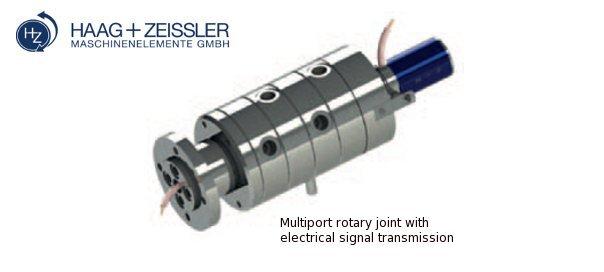

Rotary joints generally seal the passage of gases or fluids between two counter-rotating bodies. HAAG + ZEISSLER offer the new MRF multiport rotary joint for cases where electrical signals are to be transmitted at the same time, for example for the control of valves or the measurement of temperature. Thanks to its modular segmental construction with identical 2-way units, it can be flexibly designed as a 2, 4 or 6-way rotary joint. It is thus ideally suited to the supply of process media, oil, compressed air or cooling water to moving components while simultaneously transmitting measuring or control signals.

The MRF series from HAAG + ZEISSLER covers a wide range of operating pressures: the values range from 0.07 to 250 bar, depending on the speed of rotation and the medium. The MRF series is aimed at all applications with moderate speeds of rotation up to a maximum of 250 rpm.

The electrical signals are transmitted via standardised slip-ring bodies, whose slideways are specially hardened and gold-plated. This allows the reliable transmission of even the finest currents and signals for thermocouples, video and data communication or control electronics. The selected hard gold/gold combination is rustproof and provides for reliable signal transmission and constant contact quality over a long period.

Thanks to the segmental construction of the multiport rotary joint HAAG + ZEISSLER is able to considerably lower the manufacturing costs, since only a few different components are required for the construction of 2, 4 and 6-way rotary joints. Customers benefit later on during operation through savings on maintenance and service costs. The simple dismantling of the MRF series enables simple and quick access to the interior, so that any necessary replacement or cleaning work can be accomplished in no time.

The media are fed statically into the housing and sealed to the axially bored rotor. Special PTFE compounds are used as sealing elements, because they generate little friction and exhibit no stick-slip effect even after lengthy standstill periods. The rotor is made of stainless steel with a hardened, ground and polished surface. The housing segments are available in stainless steel 1.4404, brass or aluminium. Segments, seals and slip rings are kept in stock, which means that they and not the customers await their delivery.