Wieland-Werke AG presents innovative tube products at Mostra Convegno 2016

At the Mostra Convegno Expocomfort exhibition from 15th to 18th March 2016 in Milano, four business units of the Wieland-Werke AG presented their versatile tube products for refrigeration and air conditioning technology, heating technology, and sanitary facilities.

The highlights of the Wieland Group at the Mostra Convegno are:

• Copper tubes for industrial applications. Wieland Industrial Tubes offers its customers a unique combination of planning security through high reliability of delivery, flexibility through individual logistics solutions, as well as adherence to delivery dates.• On display as a part of the cuprofin-family will be cuprofin S2LD tubes benefiting from an optimized ratio of inner surface vs. tube weight. With the same inner surface these tubes are significantly lighter than competitive products and thus save costs.• TÜV-certified K65 copper tubes and the K65 system (consisting of K65 tubes and K65 fittings) are approved for high pressure applications up to 120 bar, e.g. CO2 cooling systems for supermarkets, and offer the following additional benefits: Simple and proven joining technique through brazing instead of welding, cost reduction through weight per meter reduction, as well as excellent heat transfer characteristics.

• For Air Conditioning, Wieland Thermal Solutions is presenting optimized designs of enhanced tubes for shell-and-tube heat exchangers. For flooded evaporators the new drop-in solution GEWA-B4HSL offers cost advantages. For newly designed shell and tube evaporators, the latest developments, like GEWA-B6H, offer significant efficiency increases. On display will also be a broad spectrum of materials for a wide variety of applications. In addition, the ThermalS software supporting the design of shell-and-tube heat exchangers and an innovative solution for electronic cooling in data centers will be demonstrated.

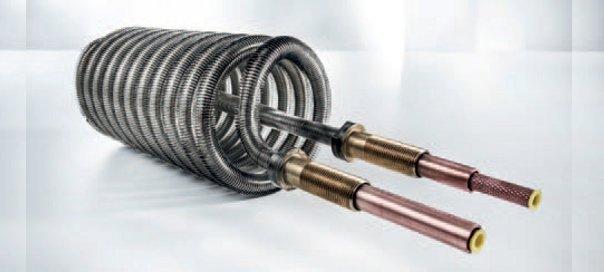

• For the area of heating technology, Thermal Solutions comes up with a newly designed heat exchanger WRKS to boost the efficiency of domestic hot water pumps. Further to this, a specially optimized double-walled safety tube with leakage channels opens up new perspectives for the heat recovery of grey-water.

• Buntmetall Amstetten is showing smooth tubes made of cupronickel-10 Caption(CuNi10) and cupronickel-30 (CuNi30) in lengths but also coil format, for e.g. heat exchangers for sea water applications and oil coolers. Thanks to the coil format the customer is very flexible and is able to produce tubes of different lengths without lots of scrap from the coil. Blank and coated Frigotec cooling tubes for refrigeration and air-conditioning installations will also be shown.

• For the area of materials for drinking water components, e.g. fittings, ball valves, etc., the business unit Pressed and Drawn Products for the product group ‘Machining Brass’ is showing a broad, innovative and reliable portfolio of hygienically approved alloys, including ECOBRASS. With ECOBRASS already today it is possible to install Pb-free, safe and economically. In addition to ECOBRASS, with AQCUARIN there is another dezincing resistant material available to replace the hygienically critical material CW602N. Since January 2016 AQCUARIN is officially listed as a hygienically suitable material.

About Wieland

The Wieland Group with headquarters in Ulm, Germany, is one of the world’s leading manufacturers of semi-finished products such as strip, sheet, tube and rod as well as special products, for example slide bearings, finned tubes and heat exchangers. Besides copper and copper alloys, Wieland also uses other metallic materials such as aluminium, steel, stainless steel and titanium. As an international company, Wieland has manufacturing companies, slitting centres and trading companies in many European countries as well as in the USA, South Africa, Singapore, China and India. The Wieland Group employs some 6,800 people worldwide, 4,400 of them in Germany.